Navigating Conduit Connectors in Australia: A Comprehensive Guide

Conduit connectors play a crucial role in electrical installations by providing secure and reliable connections between conduit pipes, fittings, and electrical equipment. In Australia, where safety standards and regulations are stringent, selecting the right conduit connectors is essential to ensure compliance and optimal performance. In this comprehensive guide, we’ll delve into the functionality, types, applications, standards, considerations, and best practices associated with conduit connectors in Australia.

Understanding Conduit Connectors

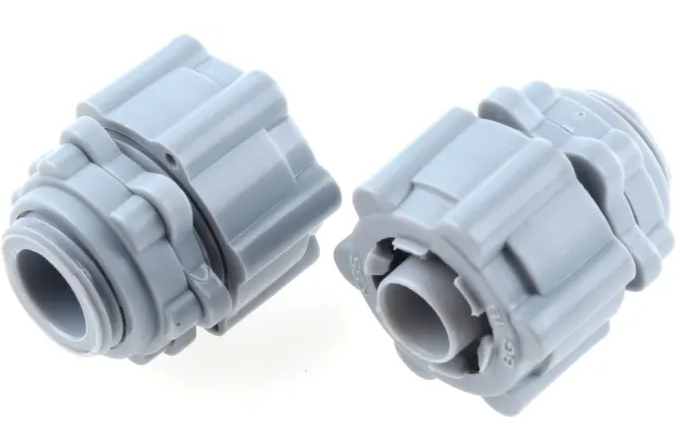

Functionality: Conduit connectors, also known as conduit fittings, are mechanical devices used to join sections of conduit pipes, terminate conduit runs, and connect conduit to electrical enclosures, boxes, or equipment. Conduit Connectors Australia provide a secure and watertight seal to protect electrical wiring from environmental hazards, moisture, dust, and debris.

Types of Conduit Connectors:

- Compression Connectors: Compression fittings use compression rings or glands to secure conduit pipes together, ensuring a tight and secure connection.

- Threaded Connectors: Threaded fittings feature male or female threads that screw onto the ends of conduit pipes, providing a secure and durable connection.

- Liquidtight Connectors: Liquidtight fittings are designed to provide a watertight seal for conduit installations in damp environments, such as outdoor or underground applications.

Applications of Conduit Connectors

Electrical Wiring: Conduit connectors are widely used in electrical wiring installations to connect conduit pipes to junction boxes, distribution panels, switches, outlets, and electrical equipment. They ensure a safe and reliable electrical connection while protecting wiring from damage.

Industrial Settings: In industrial environments such as factories, warehouses, and manufacturing plants, conduit connectors are utilized to secure conduit runs, terminate conduit runs, and connect conduit to machinery, equipment, and control panels.

Commercial Buildings: Conduit connectors play a crucial role in commercial buildings, including offices, retail stores, hospitals, and schools, where they are used to route and protect electrical wiring in walls, ceilings, and floors, as well as connect conduit to lighting fixtures, HVAC systems, and emergency equipment.

Standards and Regulations in Australia

AS/NZS 2053: This Australian Standard specifies requirements for non-metallic conduit systems, including fittings, for electrical installations. It covers dimensions, materials, performance, and testing criteria for conduit connectors used in electrical wiring installations.

AS/NZS 3000: The Wiring Rules standard outlines the requirements for electrical installations in Australia, including the selection, installation, and use of conduit connectors. It specifies the types, sizes, and installation methods for conduit fittings to ensure compliance with safety and performance standards.

Considerations for Selecting Conduit Connectors

Material: Choose conduit connectors made from materials that are suitable for the specific application and environmental conditions. Common materials include PVC, galvanized steel, stainless steel, and aluminium, each offering different levels of corrosion resistance, durability, and conductivity.

Size and Compatibility: Select conduit connectors that are compatible with the size and type of conduit pipes being used. Ensure that the connectors match the diameter, thread type, and configuration of the conduit pipes to achieve a proper fit and seal.

Environmental Conditions: Consider the environmental conditions in which the conduit connectors will be installed, such as indoor, outdoor, underground, or hazardous locations. Choose fittings with appropriate ingress protection (IP) ratings, corrosion resistance, and temperature ratings to withstand specific conditions.

Installation Best Practices

Proper Alignment: Ensure that conduit connectors are aligned correctly with conduit pipes and electrical enclosures to prevent misalignment or strain on the fittings. Use alignment guides, spacers, or adapters as needed to achieve a proper fit.

Secure Fastening: Tighten conduit connectors securely using appropriate tools and techniques to ensure a watertight seal and prevent loosening or leakage over time. Follow manufacturer recommendations for torque specifications and installation procedures.

Sealing and Waterproofing: Apply sealants, gaskets, or waterproofing compounds as needed to seal conduit connections and protect against moisture ingress, especially in outdoor or wet environments. Follow industry best practices and local regulations for waterproofing electrical installations.

Conclusion

In conclusion, conduit connectors are essential components of electrical wiring installations in Australia, providing secure and reliable connections for conduit pipes, fittings, and electrical equipment. By understanding the functionality, types, applications, standards, considerations, and best practices associated with conduit connectors, electrical professionals can ensure compliance with safety regulations and standards while achieving optimal performance and reliability in electrical installations. Whether in residential, commercial, industrial, or outdoor settings, selecting the right conduit connectors and following proper installation procedures are crucial steps in maintaining the safety, efficiency, and longevity of electrical systems across diverse applications.