How Do Servo Motors Compare to Other Types of Actuators?

In the era of precision control and automation, the choice of actuators plays a pivotal role in determining the efficiency and accuracy of various industrial processes. Among the array of actuation technologies available, servo drives and motors stand out as a cornerstone of advanced motion control systems.

Let’s explore the functionalities and applications of servo motors, contrasting them with prominent alternatives to empower a well-informed decision-making process for your next project.

Understanding Servo Drives and Motors

A servo motor is a self-contained electromechanical device that integrates a regular electric motor with feedback mechanisms and control circuitry. This unique combination allows for highly controlled rotational or linear movements. The internal feedback system, often an encoder, continuously monitors the motor’s position and transmits this data to the control unit.

The control unit then compares the actual position with the desired position and makes adjustments to the motor’s power output to minimise any discrepancies. This closed-loop system ensures precise positioning accuracy, making servo drives and motors ideal for applications demanding intricate movements.

Common Applications of Servo Motors

Servo drives and motors empower a wide range of automation tasks due to their exceptional controllability and accuracy. Here are some prominent examples:

- Robotics

They are instrumental in the precise movement of robotic arms, allowing for intricate tasks like assembly, welding, and material handling.

- CNC Machining

Servo motors ensure the accurate positioning of cutting tools in computer numerically controlled (CNC) machines, guaranteeing high-precision machining of complex parts.

- Camera Control Systems

These motors enable the precise movement of cameras in security systems, surveillance applications, and robotic photography rigs.

- Radio-Controlled Vehicles

Servo drives and motors are widely employed in radio-controlled aeroplanes, drones, and cars to control steering, rudders, and ailerons, facilitating intricate manoeuvres.

- 3D Printing

They are increasingly being incorporated into 3D printing machines to control the movement of the print head, leading to enhanced printing accuracy and detail.

Advantages of Using Servo Motors

There are various compelling reasons to consider using servo drives and motors in your project:

- Precise Control

The closed-loop feedback system ensures exceptional positioning accuracy, making them ideal for applications demanding meticulous movements.

- Versatility

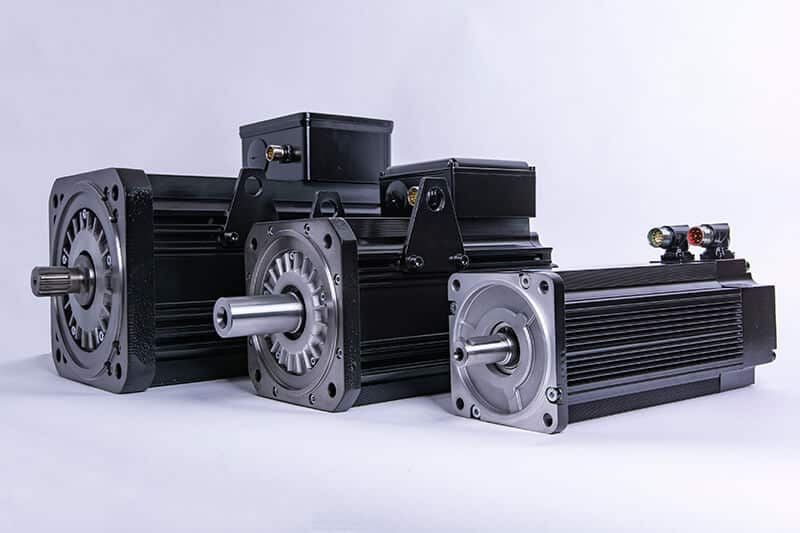

Servo drives and motors come in various sizes and torque outputs, catering to a broad spectrum of applications.

- Ease of Use

They often require minimal setup and programming compared to some actuator alternatives.

- Durability

Modern servo motors are built for endurance and can withstand repeated use in demanding environments.

Common Types of Actuators and their Comparison with Servo Motors

While servo drives and motors excel in specific applications, it’s crucial to understand how they compare to other commonly employed actuators:

- Linear Actuators

These actuators provide linear motion in a single direction, ideal for tasks requiring pushing, pulling, or lifting objects in a straight line. Linear actuators offer high force output and simplicity but lack the precise positioning capabilities of servo motors.

- Stepper Motors

Stepper motors offer precise control over angular movements in discrete steps. They are more cost-effective than servo drives and motors but may exhibit slight inaccuracies at lower speeds and lack the continuous rotation capability of servo motors.

- Solenoids

These are simple electromechanical devices that convert electrical energy into a linear pushing force. They are low-cost, have a fast response time, and are suitable for basic on/off motions but lack the controllability and precision of servo drives and motors.

The Importance of Partnering with Reputable Electrical Brands

Selecting the right servo motor and ensuring its successful implementation necessitate a reliable source of equipment and expertise. Partnering with a reputable electrical brand offers several benefits:

- Extensive Product Portfolio

- Technical Support

- Quality and Reliability

- Compliance with Regulations

Take Your Automation to the Next Level: Explore the World of Servo Motors Today

While various types of actuators serve diverse industrial needs, servo drives and motors stand out as the epitome of precision and efficiency in motion control. Their unparalleled performance and versatility make them indispensable assets in today’s automation landscape.

By partnering with reputable electrical brands, businesses can harness the full potential of servo motors and unlock new possibilities for innovation in the digital age.